No products in the cart.

SELF-DRILLING SCREWS

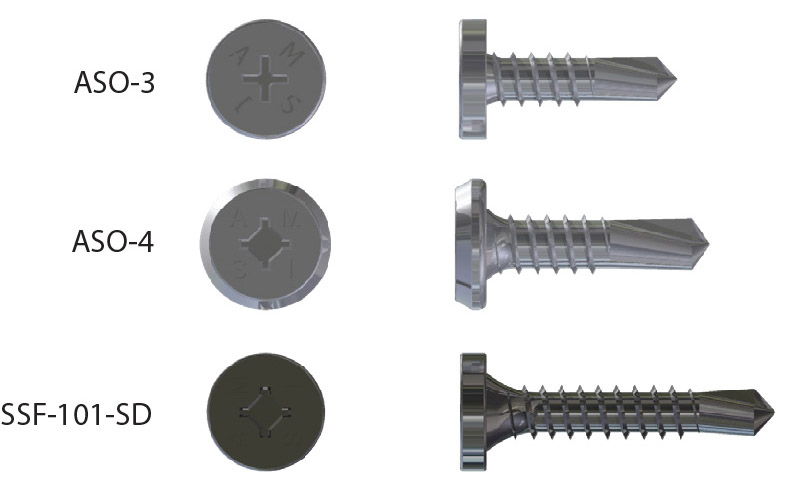

AMSI self-drilling screws are an excellent choice for all metal-to-metal fastening requirements. All AMSI self-drilling screws feature panhead design, with either phillips or combo drive. Head thickness is 0.084"+/-.

- ASO-3 is #2 Phillips drive

- ASO-4 is combo drive

- SSF-101-SD is combo drive

- Meets or exceeds ASTM C-1513 and/ or ASTM C-954

- Galvanized or 410 stainless steel

SELF-DRILLING PANHEAD SCREW

| Part Number | Description | Thread | Length | Coating | Drive | Box Qty | Price |

|---|---|---|---|---|---|---|---|

| ASO-3 | Panhead SD Screw | 10-14 | 5/8" | White Zinc | Phillips | 7,500 | CALL for Pricing |

| ASO-4 | Panhead SD Screw | 12-12 | 3/4" | White Zinc | Combo | 5,000 | CALL for Pricing |

| SSF-101-SD | Panhead SD Screw | 10-12 | 1" | Stainless | Combo | 6,000 | CALL for Pricing |

*White Zinc is galvanized electroplating.

*410 Stainless Steel fastener, NO COATING.

Note that all stainless steel is magnetic, including 410.

AMSI#12 SCREWS ULTIMATE VALUE CHART

| Diameter | Nom. Screw Diameter (inches) | Metal Gauge/1lb | Tension (Pull) lbs 1pc | Shear (lbs) Metal to Metal | Minimum Torsional Strength (lbs) |

|---|---|---|---|---|---|

| 12 | 0.216 | 20 | 314 | 698 | 92 |

| 12 | 0.216 | 18 | 472 | 983 | 92 |

| 12 | 0.216 | 16 | 735 | 1556 | 92 |

| 12 | 0.216 | 14 | 1057 | 2072 | 92 |

| 12 | 0.216 | 12 | 1242 | 2210 | 92 |

| 12 | 0.216 | 0.156" | 2685 | 92 | |

| 12 | 0.216 | 0.187" | 3394 | 92 |

ULTIMATE VALUE CHARTS:

Steel: Screws are driven into steel were driven with three (3) exposed threads on the off-side of the connection, then pulled out with the testing machine.

Wood: Screws were driven 3/4" into the wood material then pulled out with the testing machine.

Note that all results were obtained in strict adherence to ASTM test protocols. These ultimate figures are offered only as a guide and are not guaranteed in any way by AMSI (Architectural Metal Specialties Inc.). A 4:1 safety ratio is recommended.

INSTALLATION GUIDELINES:

0-2500rpm screwgun with torque adjustment is recommended. Overdriving may result in fastener failure or strip-out of the work surface.

The fastener is fully seated when the screw head's bearing surface is flush with the surface.

Always were eye protection when driving screws. Screws and driver bits may fracture or shatter. Serious injury and/or blindness can occur.